Ball Joint Diagnosis and Repair

Ball joints have been on vehicles for more than 70 years. That’s almost as long as Hollenshade’s has been serving drivers and families in Towson. Prior to a ball joint, components call kingpins were utilized. However, the component most attributable to the quality ride and control we’ve grown accustomed to on modern vehicles is the ball joint. This is because the ball joint is a critical component in a vehicle with independent suspension.

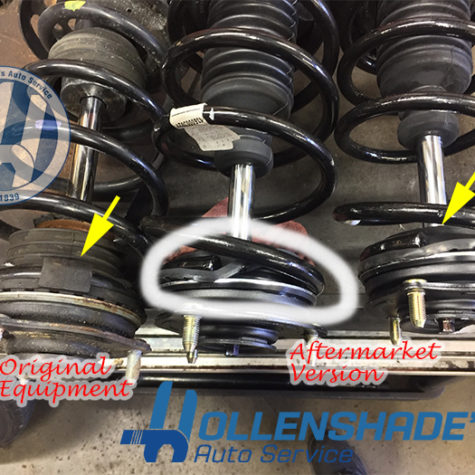

While the basics of the ball joint have remained the same, the materials have improved along with design refinements that enable the joint to last longer and carry greater loads. For aftermarket replacement ball joints many manufacturers have focused on improving the OE design or adding serviceability to the ball joint.

The experts at Hollenshade’s in Towson can address any problems you may experience with the steering or suspension on your vehicle. Please contact us for an appointment or to ask us a question about a steering and suspension issue or repair for your vehicle.

Ball Joint Friction

The ball joints on a vehicle generate friction that can change how the steering feels and operates. Ball joint components such as the Belleville washer, ball/socket materials, and the size of the joint can determine how much friction is generated within a ball joint. Over time as the ball joint wears, the material in the socket is worn away by movement and friction. Because the stud is made of hardened steel, the socket bears most all of the component wear. Once enough wear occurs the stud is able to move. For ‘loaded‘ ball joints, this movement can create lateral (side-to-side) or axial (up-and-down) play. Some steering and suspension configurations involve lifting the vehicle to unload the suspension in order to properly evaluate the amount of play in the ball joint. Using a low quality ball joint can result in increased friction in the vehicle steering and a different feel when behind the wheel. Excess friction in a ball joint can also result in a symptom called ‘memory steer’ where the steering wheel does not want to return to center after a turn.

Ball Joint Grease

Ball joints all use lubrication in one form or another. Grease reduces friction and wear on the surfaces of the ball and socket. For greaseable joints, it is recommended that a National Lubricating Grease Institute (NLGI) certified GC/LB rating is used for ball joints. This grease is designed to withstand extreme pressures, oxidation and prevent corrosion. Use of a general purpose or non-certified chassis grease will not offer the same level of protection as a NLGC GC/LB certified grease.

During maintenance interval services greaseable fittings are lubricated through a ‘Zerk‘ fitting. Performing this service is not simply topping off the grease; this maintenance item is also responsible flushing the joint of debris, moisture and contaminants. Most greaseable joints have a relief valve where the boot meets the stud. When grease is pumped into the joint, the old grease will be forced out the relief valve. The proper amount of grease in the joint and boot acts as a seal that occupies the space that otherwise would be filled by contaminants.

Ball Joint Materials Matter

Modern day ball joints have benefited from better materials that improve every year. High-tech synthetic materials are now used on most ball joint boots instead of traditional rubber. These materials are more pliable and last longer under the higher temperatures commonplace on newer vehicles. These synthetic materials hold up to the heat generated from the brakes and environmental wear due to ozone and road grime/fluids better than their predecessors. New style ball joints boast a more compact form factor thanks to better engineering and design tools.

Another aspect of the design improvements included in a modern ball joint is the method of sealing the boot to the base of the stud. In the past, many boot designs were a friction fit where the elasticity and bellows of the boot held it in place. Over time, the boot material would lose its elasticity and leave the joint exposed to the elements. New boot designs are using metal rings to hold the boot in place. Some ball joint manufactures are also engineering the boot and joint together with slots in the base and stud to secure the boot.

Ball Joint Inspection

Proper inspection of a ball joint requires an understanding of the steering and suspension system configuration of the vehicle. Loaded ball joints require the vehicle be supported at the control arm to relieve pressure created by the weight of the vehicle. A short/long arm (SLA) suspension configuration has the coil spring over the top arm and thus the upper ball joint is loaded. On this type of configuration the weight must be removed from the upper control arm. Some ball joints have built-in wear indicators. These type of ball joints are not very prevalent anymore but if found are checked with the vehicle on its wheels. A follower-type ball joint is checked by compressing the Belleville washer to observe axial end play. Ball joint evaluation on a strut-type suspension is more straightforward as lifting the vehicle and allowing the strut to fully extend enables the technician to observe for excessive axial ball joint movement. For more information about ball joint inspection call 410-828-5750 or email us today!

Ball Joint Installation

It is important that a trained professional be selected to perform the ball joint replacement on your vehicle. Doing so will ensure a lasting repair. Improper installation, including spinning the stud in the socket, will damage the joint by heat and wearing motion. Using the bolt heads or recessed Allen heads to hold the stud is critical. Moreover, an experienced professional will know what style of ball joint is being installed. Changes in ball joint technologies have been incorporated to accommodate aluminium steering and suspension knuckles. These style ball joints require meeting an accurate torque specification that usually involves an initial torque followed by an angle measure. Over-tightening a tapered ball joint stud can damage not only the new ball joint but the knuckle as well.