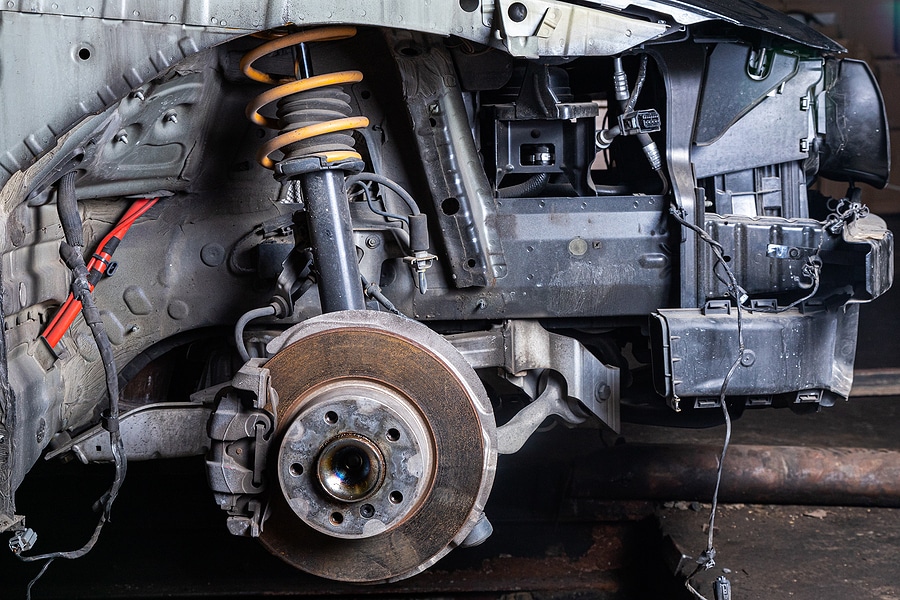

When it comes to maintaining your vehicle’s braking system, there’s often confusion about whether rotors need to be machined, replaced, or left alone. At Hollenshade’s Auto Repair in Towson, we specialize in professional brake repair services, and we’re here to clear up common questions about brake rotors, safety standards, corrosion, coatings, and more. Whether you’re researching brake rotor replacement, automotive repair, or car maintenance tips, this guide offers insights backed by industry experience and engineering standards.

Does a Rotor Need to Be Machined?

No.

Brake rotors do not need to be machined by default. In most modern brake systems, replacing worn rotors is safer and more effective than machining them. Machining removes metal from the rotor surface, which can reduce its ability to dissipate heat and resist warping. In many cases, replacement rotors are engineered with safety and performance in mind and are the better long-term option for reliable brake performance.

What Causes a Rotor to Crack?

Brake rotors do not typically crack from impact—such as hitting a pothole or curb. Instead, they fail due to heat-related stress and repeated thermal cycling (heating and cooling). Every time the brakes are applied, the rotor heats up and expands. After the calipers release, the rotor cools and contracts. Over time, this expansion and contraction cycle causes metal fatigue, which can lead to cracking or structural failure.

Replacement brake rotors that are properly engineered and manufactured include built-in features to manage this stress. It begins with the design of the rotor fins and hat structure, especially the critical area where the rotor plates connect to the hat. Some rotors include heat dams, which help regulate expansion and control temperature buildup.

Additionally, the manufacturing process plays a major role in durability. The energy and heat used during casting and how the rotor is cooled before it is machined can increase or reduce internal stress. This is why choosing high-quality brake parts from certified auto repair shops like Hollenshade’s matters.

Are There Any Safety Certifications or Requirements for Replacement Rotors?

In the United States, replacement brake rotors and pads are not required to meet government safety standards. The U.S. Department of Transportation (DOT) tests brakes only as part of the complete vehicle system during new car certification. However, aftermarket rotor manufacturers must still design their products to match or exceed OEM (original equipment manufacturer) performance.

Deviating from original equipment designs to save money can compromise the safety of the brake system. The Society of Automotive Engineers (SAE) has developed a series of tests using a brake dynamometer to evaluate rotors for crack resistance. One such test subjects the rotor to 150 heat cycles, bringing the rotor from cold to high temperature repeatedly to uncover weaknesses in metallurgy or structure. This type of stress testing helps ensure long-term rotor reliability.

Can Corrosion Compromise the Structure of the Rotor?

Yes.

Excessive corrosion, especially around critical stress points, can lead to rotor failure. Rust buildup may weaken the structure of the rotor and reduce its ability to handle braking forces. Also, wearing the rotor surface beyond discard thickness increases the likelihood of structural failure. This is why regular brake inspections are essential to keep your vehicle safe on the road, especially in Baltimore’s variable climate where salt and moisture accelerate corrosion.

Do Special Finishes on the Rotor Help Its Performance?

Not significantly.

Many premium brake rotors feature a dull silver coating, often referred to as a Geomet coating. While this coating does not enhance braking performance directly, it prevents corrosion on non-friction surfaces such as the rotor hat and fins. Once the brake pads engage, the coating on the friction surface is quickly removed. However, the coating is designed not to contaminate the brake pad material and can aid in proper bedding of new pads.

Geomet-coated rotors are ready to install out of the box, and they do not require cleaning to remove grease or oil—unlike some traditional uncoated rotors. This convenience makes them a popular choice for automotive shops and brake repair technicians.

Trust Hollenshade’s for Professional Brake Repair in Towson, MD

At Hollenshade’s Auto Repair in Towson, we take your safety seriously. Our experienced technicians specialize in brake service, rotor and pad replacement, and comprehensive vehicle diagnostics. We use only trusted, high-quality parts and follow manufacturer specifications to ensure your vehicle performs safely and reliably.

Whether you’re experiencing squeaking, vibration, or reduced stopping power, our team can help you get back on the road with confidence. Serving the Baltimore metropolitan area for decades, Hollenshade’s is proud to be your go-to mechanic shop in Towson, MD for brake repair and more. Contact us to schedule your appointment now.